However the high hardness and high vanadium carbide content make it more difficult to grind after heat treatment compared to m2 and other high speed steels.

M4 tool steel yield strength.

This page shows summary ranges across both of them.

Cpm rex m4 hc high speed steel is an extremely versatile high speed steel that provides a unique combination of high wear resistance with high impact toughness and transverse bend strength.

Rockwell c30 hard heat treatable.

Griggs steel color code.

A large volume of vanadium carbides provides the high wear resistance.

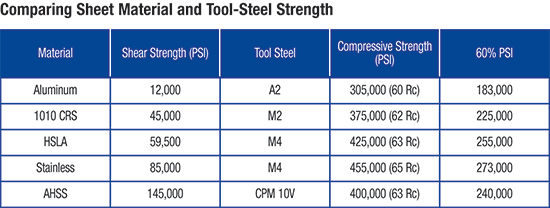

Compare popular tool steel grades a2 m2 d2 s7 o1 using the chart below.

T11304 is the uns number.

A2 d2 and m4.

Sae aisi m4 steel is a tool steel.

The properties of sae aisi m4 steel include two common variations.

Mechanical properties of alloy steel uns t11304 m4 high speed tool steel hardness annealing.

Choose from our selection of grade m2 tool steel including over 500 products in a wide range of styles and sizes.

64 hrc min different hardness according different tempering temperature.

Compare grades using mechanical properties including abrasion resistance toughness size stability machinability and grindability.

Its sweet spot hardness is 54 56 hrc and a yield strength of 235 ksi at a 500 degree fahrenheit temper.

Hardness vs compressive yield strength.

A2 tool steel is an air hardening cold work chromium alloy die steel that is preferable to o1 tool steel in applications requiring greater size stability machinability and safer hardening.

M4 is the designation in both the sae and aisi systems for this material.

248 hb max q t.

For more specific values follow the links immediately below.

At those levels it achieves a good balance of strength and ductility.

The high carbon content enables m4 steel to be hardened in excess of 65hrc.

Hardness after heat treatment.

The high impact toughness and high transverse bend strength are results of the fine grain.

Cpm rex m4 hc powder metal high speed steel.

Hs 6 5 4 e m4 skh 54 stark.

The wear resistance properties and cost place a2 between that of o1 and d2 tool steel making it a good all purpose grade for many applications.

Chemically the microscopic carbide.